How an Aluminum Casting Company contributes to sustainability in industries

Wiki Article

Discovering the Important Applications and Uses of Light Weight Aluminum Shop in Modern Production

Aluminum factories play a crucial duty in modern manufacturing, serving diverse markets with their special properties. From automotive parts that enhance gas performance to aerospace structures that focus on weight, light weight aluminum's convenience is evident. Its applications encompass building and customer electronic devices, highlighting its longevity and energy efficiency. However, the innovations in aluminum spreading strategies and future fads call for a closer assessment, as they may redefine its impact on manufacturing.The Function of Light Weight Aluminum Foundries in Automotive Production

As the automotive industry increasingly prioritizes lightweight products to boost gas effectiveness and performance, light weight aluminum factories have become essential factors to producing procedures. These shops focus on producing elements that meet the rigid demands of modern-day vehicles, such as engine blocks, transmission real estates, and structural components. Aluminum's favorable buildings-- such as high strength-to-weight proportion, rust resistance, and outstanding thermal conductivity-- make it an ideal choice for vehicle applications.Aluminum factories make use of advanced spreading strategies, consisting of die spreading and sand casting, to produce complex and durable components. This capacity allows makers to maximize designs for performance while minimizing weight. The usage of aluminum additionally sustains sustainability goals, as it is very recyclable and reduces energy usage in automobiles. By facilitating the integration of aluminum right into auto design, foundries play a critical function in forming the future of the auto industry, promoting efficiency and development throughout the board.

Aerospace Applications: Lightweight Solutions for Trip

Light weight aluminum shops play a substantial duty in the aerospace sector, where the demand for lightweight materials is paramount for enhancing fuel effectiveness and efficiency in airplane. The unique residential or commercial properties of aluminum, including its high strength-to-weight proportion and deterioration resistance, make it an excellent option for different aerospace elements. These components consist of structural components, engine coverings, and touchdown equipment, which add to total airplane performance.The use of aluminum alloys, particularly those developed via innovative spreading methods, permits the production of detailed layouts and complicated shapes while minimizing weight. In addition, light weight aluminum's recyclability aligns with the aerospace sector's sustainability objectives, minimizing environmental impact. With continual innovations in light weight aluminum factory modern technologies, producers can optimize manufacturing procedures, resulting in increased efficiency and lowered expenses. As the aerospace industry increasingly focuses on advancements that improve efficiency, light weight aluminum foundries will certainly stay integral to creating lightweight remedies for contemporary trip.

Building and Construction: Enhancing Architectural Stability

In the building and building and construction industry, a significant emphasis is positioned on improving architectural stability via making use of light weight aluminum. Understood for its high strength-to-weight ratio, light weight aluminum provides durability without endangering on weight, which is important in modern architectural designs. Its resistance to rust additionally guarantees durability, making it a perfect product for various architectural components, consisting of beams, structures, and cladding.Aluminum also promotes ingenious layout possibilities, permitting engineers and engineers to create visually pleasing structures while maintaining safety and security criteria. The material's flexibility enables its application in both industrial and household tasks, from high-rise buildings to bridges. In addition, advancements in light weight aluminum factory strategies have enhanced the accuracy of aluminum elements, guaranteeing they meet stringent building regulations. Generally, the integration of aluminum in building not just boosts architectural honesty but likewise adds to sustainable structure techniques, given its recyclability and energy-efficient production techniques.

Consumer Electronic Devices: The Rise of Aluminum in Technology

In the domain name of consumer electronics, light weight aluminum has actually obtained prestige because of its light-weight style advantages and superior thermal conductivity. This shift not only enhances item transportability however additionally boosts tool efficiency by efficiently dissipating warm. As technology continues to evolve, the duty of light weight aluminum in producing streamlined and efficient tools is increasingly significant.Light-weight Style Advantages

As customer electronic devices progress, the demand for light-weight yet long lasting materials has actually risen, making aluminum a significantly prominent choice amongst makers. Its low thickness enables the production of smooth devices that are simple to bring and use, substantially improving portability. The strength-to-weight ratio of light weight aluminum guarantees that items can endure day-to-day wear and tear without endangering performance. In addition, the malleability of light weight aluminum enables makers to make complex shapes and types, better adding to cutting-edge appearances and performance. This light-weight quality likewise plays a necessary role in energy performance, as lighter devices need much less power to operate. Because of this, light weight aluminum not only satisfies the advancing visual demands however additionally aligns with the modern emphasis on sustainability in customer electronic devices.Thermal Conductivity Advantages

Thermal conductivity is an essential consider the efficiency of consumer electronics, and light weight aluminum master this domain name. Its high thermal conductivity enables efficient warm dissipation, which is necessary for maintaining ideal operating temperature levels in devices such as smartphones, laptop computers, and pc gaming consoles. By facilitating rapid warmth move far from delicate parts, light weight aluminum aids prevent overheating, consequently boosting efficiency and lengthening device long life. Furthermore, the lightweight nature of aluminum complements its thermal properties, making it a suitable choice for portable technology. As manufacturers increasingly focus on efficiency and power effectiveness, aluminum's role in thermal management comes to be also a lot more considerable, resulting in its growing adoption in modern-day electronic styles. This fad emphasizes light weight aluminum's significance in consumer electronic devices advancement.Marine Industry: Deterioration Resistance in Harsh Settings

Rust resistance is a crucial consider the aquatic market, where equipment and frameworks are regularly revealed to extreme aluminum casting company saltwater settings. Light weight aluminum, specifically in its alloy types, uses significant advantages hereof. Its all-natural oxide layer offers a safety barrier that protects against rust, making it perfect for vessels, anchors, and other aquatic applications.Marine-grade aluminum alloys, such as 5083 and 6061, are especially developed to withstand the destructive effects of deep sea and climatic conditions. These alloys not just resist deterioration but likewise maintain architectural stability and toughness gradually. Applications range from hulls and superstructures of ships to components in overseas systems.

The lightweight nature of light weight aluminum further improves its viability, enabling enhanced gas efficiency and simplicity of handling - Casting Foundry. As the aquatic industry remains to concentrate on sturdiness and efficiency, aluminum stays an essential material option for standing up to corrosion in demanding marine setups

Technologies in Aluminum Spreading Techniques

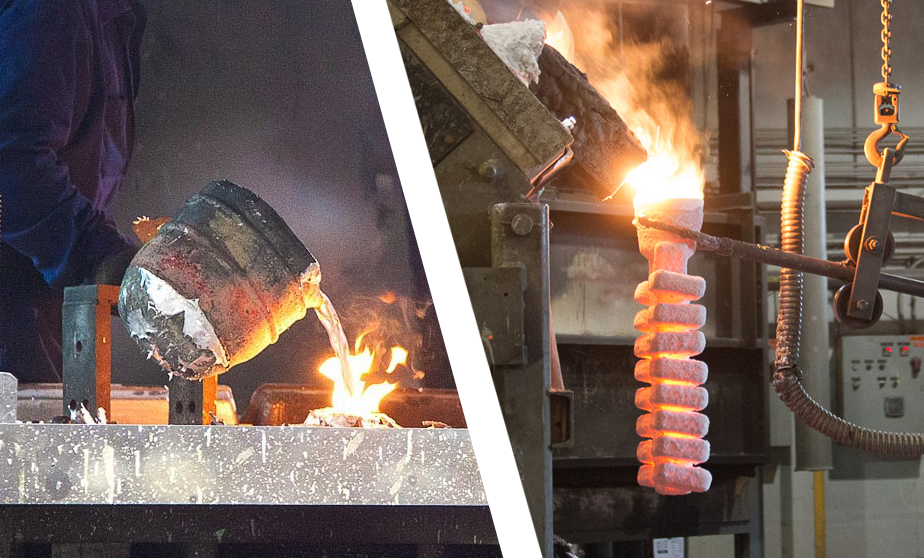

While traditional aluminum casting techniques have actually offered the sector well, recent developments are changing the landscape of light weight aluminum manufacturing. Methods such as 3D printing of cores and mold and mildews are getting grip, allowing for rapid prototyping and reduced lead times. This development allows makers to produce intricate geometries that were formerly hard to attain with standard spreading approaches. In addition, innovations in die-casting technology, including using high-pressure die-casting (HPDC), have improved the precision and surface area coating of actors light weight aluminum parts, bring about boosted efficiency in various applications.Moreover, the adoption of financial investment spreading has permitted greater design liberty and lowered product waste. Casting Foundry. Technologies in alloy structures are likewise significant, as they boost mechanical properties and deterioration resistance. Generally, these developments not just enhance production procedures yet also add to more lasting practices within the aluminum factory sector, making it adaptable to the evolving demands of modern manufacturing

Future Trends in Light Weight Aluminum Factory Manufacturing

The future of aluminum factory manufacturing is poised for considerable makeover with automation, boosting efficiency and precision in making procedures. Sustainable methods are significantly becoming a concern, as shops seek to reduce their ecological influence while meeting growing regulatory demands. Furthermore, innovations in alloy development will allow the production of more powerful, lighter products tailored for diverse applications, driving development in the market.

Automation in Shop Processes

Sustainable Manufacturing Practices

A growing focus on lasting manufacturing methods is reshaping the future of aluminum shop production. Industry leaders are increasingly adopting energy-efficient modern technologies and reusing campaigns to minimize waste and lower carbon impacts. Making use of recycled light weight aluminum considerably decreases energy intake compared to key aluminum manufacturing, making it a preferred selection for environmentally aware producers. In enhancement, ingenious spreading techniques are being created to enhance material performance and decrease exhausts. Companies are likewise spending in renewable resource resources, such as solar and wind, to power their operations sustainably. Aluminum Casting. By integrating these techniques, the aluminum factory sector not just meets regulative needs but likewise reacts to customer demand for greener products, eventually leading the way for a more sustainable production landscapeAdvanced Alloy Growth

Developments in light weight aluminum alloy development are readied to play a significant function in the future of shop production, particularly as sustainability and performance needs escalate. The market is increasingly focusing on creating high-strength, lightweight alloys that can hold up against extreme conditions while reducing environmental effect. Scientists are discovering cutting-edge make-ups, such as aluminum-lithium and aluminum-scandium alloys, which assure enhanced mechanical residential properties and decreased weight. In addition, the combination of sophisticated manufacturing methods, including additive manufacturing and precision casting, enables even more facility geometries and lowered product waste. As governing stress and customer preferences change in the direction of greener alternatives, the development of energy-efficient and recyclable alloys will be necessary. The future landscape of light weight aluminum factory production rests on these improvements in alloy modern technology.

Often Asked Inquiries

What Are the Environmental Influences of Aluminum Factory Operations?

Light weight aluminum shop operations can cause significant ecological impacts, including greenhouse gas exhausts, energy intake, and waste generation. Additionally, incorrect monitoring of pollutants might bring about dirt and water contamination, impacting neighborhood ecological communities and neighborhoods.How Does Light Weight Aluminum Recycling Affect Foundry Processes?

Light weight aluminum recycling enhances shop processes by giving an affordable resources, lowering power usage and emissions. This lasting practice raises effectiveness, minimizes waste, and supports the round economic climate, profiting both makers and the environment.What Security Measures Are Carried Out in Aluminum Foundries?

Aluminum shops execute numerous safety procedures, including personal protective devices, appropriate ventilation systems, normal security training, fire prevention methods, and devices maintenance procedures to lessen hazards and guarantee a risk-free functioning environment for all workers.Just How Do Foundries Guarantee Quality Control in Aluminum Casting?

Foundries guarantee quality assurance in aluminum casting through extensive product examinations, precise temperature level surveillance, standardized treatments, and routine screening of cast products. These steps assist maintain consistency, decrease flaws, and meet sector specifications efficiently.What Are the Expense Consider Light Weight Aluminum Foundry Production?

Cost consider light weight aluminum shop production include basic material prices, power usage, labor costs, devices maintenance, and overhead expenses. Additionally, manufacturing quantity and intricacy of styles considerably influence general manufacturing costs and profitability.

As the automotive sector significantly focuses on light-weight materials to improve gas efficiency and performance, light weight aluminum factories have become important contributors to making procedures. Light weight aluminum foundries play a significant duty in the aerospace industry, where the need for light-weight products is paramount for boosting gas performance and performance in airplane. Additionally, advancements in aluminum foundry strategies have actually enhanced the precision of light weight aluminum components, ensuring they meet rigorous building codes. While traditional light weight aluminum casting methods have actually offered the market well, recent innovations are changing the landscape of aluminum production. The use of recycled aluminum considerably decreases energy usage compared to main aluminum production, making it a favored selection for ecologically conscious makers.

Report this wiki page